Hybrid rockets are a class of rockets that use fuel & oxidizer in different phases (usually solid fuels and liquid oxidizers), unlike solid rockets which use both fuel and oxidizer mixed and combined into the same solid matrix or liquid rockets which store the fuel and oxidizer in the liquid phase. Hybrid rockets are cheap, safe and relatively simple. Further, they allow for throttling, cessation and restart of the engine in multiple cycles- things that cannot be done with solid rockets, and have a higher density specific impulse than liquid rocket engines.

However, for all their advantages, hybrid rockets suffer from two critical disadvantages that impedes wider scale application of this technology- low fuel regression rates (which limits thrust output for a given burning surface) and problems associated with ignition. Solving problems associated with ignition is the principle focus of this research effort.

Conventional igniters used in hybrid rockets add weight and complexity to the system. Further, for conventional ignition systems, there is a time delay between initiation of the ignition device and melting/pyrolysis of the fuel and this delay is not desirable for applications where accurate timing of ignition/re-ignition is of paramount importance. Motors using catalytic igniters degrade over time. Ignition systems that use a separate solid fuel for engine start face a situation wherein the igniter fuel runs out while there is still fuel remaining in the motor, thereby leading to wastage.

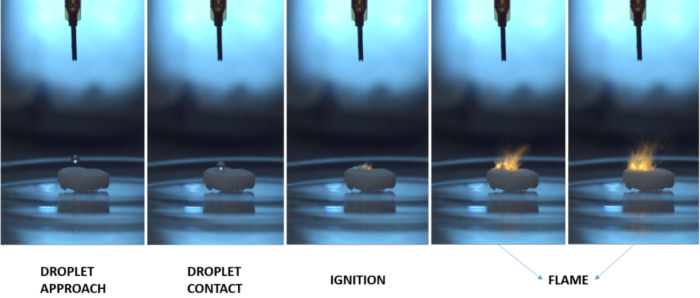

A potential solution to the problems elucidated in the preceding paragraph is hypergolic ignition. In this type of ignition, fuel and oxidizer ignite immediately upon contact, without the use of external spark/heat/energy. The primary figure of merit to characterize and compare hypergolic fuel-oxidizer combinations is the ignition delay- the time taken for a reactant combination to achieve ignition. Low ignition delay is important for smoother operation of hypergolic hybrid rocket motors. “Drop-tests” are a standard experimental method of characterizing ignition delay. Here, a drop of an oxidizer is dropped on top of a fuel and the time to ignition is measured.

The present research focuses on characterizing the performance of a polyethylene-based fuel and high concentration hydrogen peroxide oxidizer combination as a suitable hypergolic hybrid rocket fuel. At this stage of the research, experiments are being carried out to study ignition delay and the various parameters that influence it. The figure below shows a typical drop-test. A drop of high concentration hydrogen peroxide (oxidizer) makes contact with a polyethylene-based pellet (fuel). The subsequent ignition event is recorded and analyzed.